6-Figure Ops Savings

“Keyan really meticulously got costs down. He saved us multiple 6-figures in recurring costs for ops. And of course, that’s something that’s going to scale for us.

”

Summary

After strong early success in the USA market, Freak Athlete decided to launch international.

We valued speed over margin optimization. So we set up our international supply chain as fast as possible.

We got to market fast and grew our international presence into a sizable portion of the business.

Now with a more stable supply chain, we thought, what are we leaving on the table, both domestically and abroad?

That’s when we went to work and started chipping away on margin.

Improving last mile rates, lowering our pick and pack costs, packaging bundle products together, finding invoice errors, re-collecting GST & VAT claims, reclaiming port fees, lowering our processing fees, and more.

We learned to be scrappy and fight for every single dollar, and Freak Athlete now has a foundation that will save them millions as they scale.

3PL / Distribution Center Visits

During my time at Freak Athlete, I made in person visits to over 10 3pls.

Setting up a great supply chain is not just about getting great prices, but also about setting up great partnerships.

There is simply no better way to build a partnership than to have a personal relationship with the team that will be handling and distributing your products.

Over time, I’ve been able to decipher between great and not so great distribution centers.

Distribution Center Vetting Guide -> click here

Lowering Our Cost of Goods Sold

After setting up our global supply chain, the next objective was to improve our overall landed cost.

Our cost structure was already pretty strong, but wanted to find Freak Athlete at least 5% savings across the entire supply chain from manufacturing to distribution.

I explored the entire supply chain journey from manufacturing to the customers doorstep across all SKU’s / Channels to find savings.

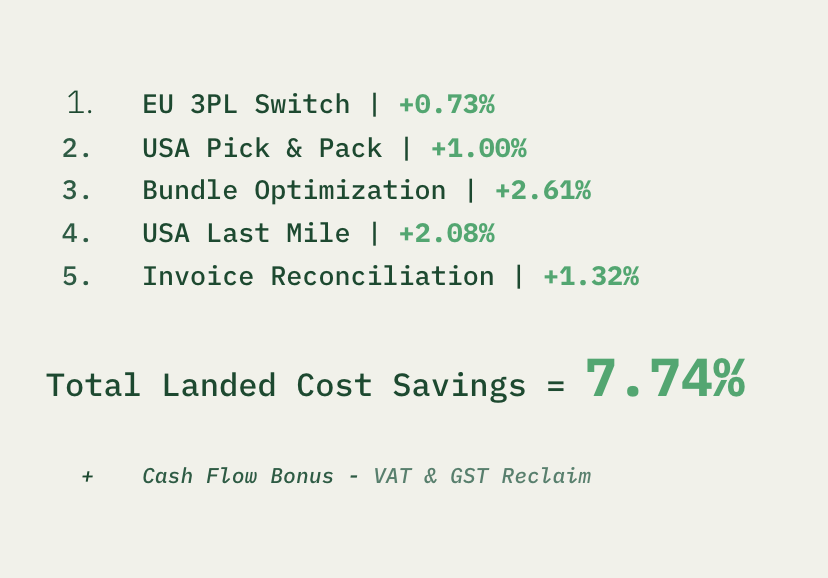

We exceeded expectations by finding and executing on a 7.74% cost of goods sold savings.

That means that for every unit sold, we make 7.74% more profit.

See the photo to the right for a quick snapshot of results ->

As of April 2025 (still improving)

Areas of Saving

How did we get our results? Let’s dive into some the specifics.

#1 - Bundle Packaging Optimization

By deeply understanding our rate card pricing, we were able to strategically stay under certain weight limits and re-package our products for huge savings.

#2 - Invoice Reconciliation

We took pride in reviewing and deeply understanding every invoice across our entire supply chain. After reviewing our last mile invoices, we found an incorrectly applied overweight surcharge which we proved was incorrect and won back.

#3 - Last Mile Carrier Optimization

By switching to a more competitive carrier for certain shipping zones and product weights, we were able to save big on shipping across our supply chain.

#4 - Pick & Pack Optimization

Powered by data and comparables, we were able to help our 3pl understand our most common order, our large bundle, consisting of 3 boxes (122 lbs, 40 lbs, 19 lbs) and lowering the price.

#5 - 3PL Partnerships

By comparing dozens of 3pl’s side by side, we were able to negotiate and achieve the most cost effective fulfillment & last mile without losing quality.

#6 - VAT & GST

We made sure to follow the paper trail and recover all B3, GST, and shipping related documents to submit to the government and receive cash back on all import containers.

Free Audit Report - Within 24 Hours of our Call

If you can’t find a time slot that works for you, send me an email at keyan@ironmargin.com and we’ll make it work.