How JSkis Built a Leaner, Smarter Supply Chain..Right Here in North America

Most ski brands rely on overseas factories, long lead times, and murky cost structures.

Not JSkis.

They design their skis in Vermont, build them in Quebec, and ship directly to customers out of a warehouse in Knoxville. No middlemen. No 60-day ocean freight wait. Just full control and total transparency.

Here’s what they nailed:

1. Factory Ownership = Speed & Control 🔧

The founder knows EVERYTHING.

When the founder’s at the factory, decisions move fast.

Many brands have never met their manufacturers in person. They communicate via email. Even with a reputable factory, iteration is slow and errors slip through. If you want to build something exceptional, your rate of iteration and ability to catch issues needs to be extremely fast.

That’s why if manufacturing isn’t your own—like JSkis—a core member of your team should be living at the factory.

2. No 60-day Ocean Wait - Made in Quebec 🇨🇦

Every brand would love to finish a production batch and get it to their customer immediately.

Unfortunately, for many industries, this is unfeasible. Many products are too big and bulky to ship air freight, so if they’re made overseas, you need to wait 1–2 months to get your hands on the product.

In a world with supply chain uncertainty, this is one less thing JSkis has to worry about. They produce everything in small batches and are known for their creative art and limited drops. They have a private label MOQ of 50 units.

Because of this, they’ve been able to collaborate with brands like Mountain Dew and Dos Equis. If you’re K2 Sports, you're making massive batches in China, so if you want to private label skis for a brand, it would likely need to wait.

That flexibility is a unique competitive advantage in their industry.

No middlemen. No markups. Just full cost control.

JSkis has full cost transparency & control.

They source their own maple and carbon fiber, and their manufacturing employees are in-house. There’s nothing hidden. I’ve seen the lack of transparency in logistics firsthand working for brands and talking with manufacturers and logistics partners.

A bad logistics partner is one who wins on your ignorance and there’s plenty of partners out there who will overcharge you.

J-Skis does not need to worry about this.

Simple channels, simple pricing, fewer headaches.

They keep things so simple and focus on their craftsmanship and telling their story.

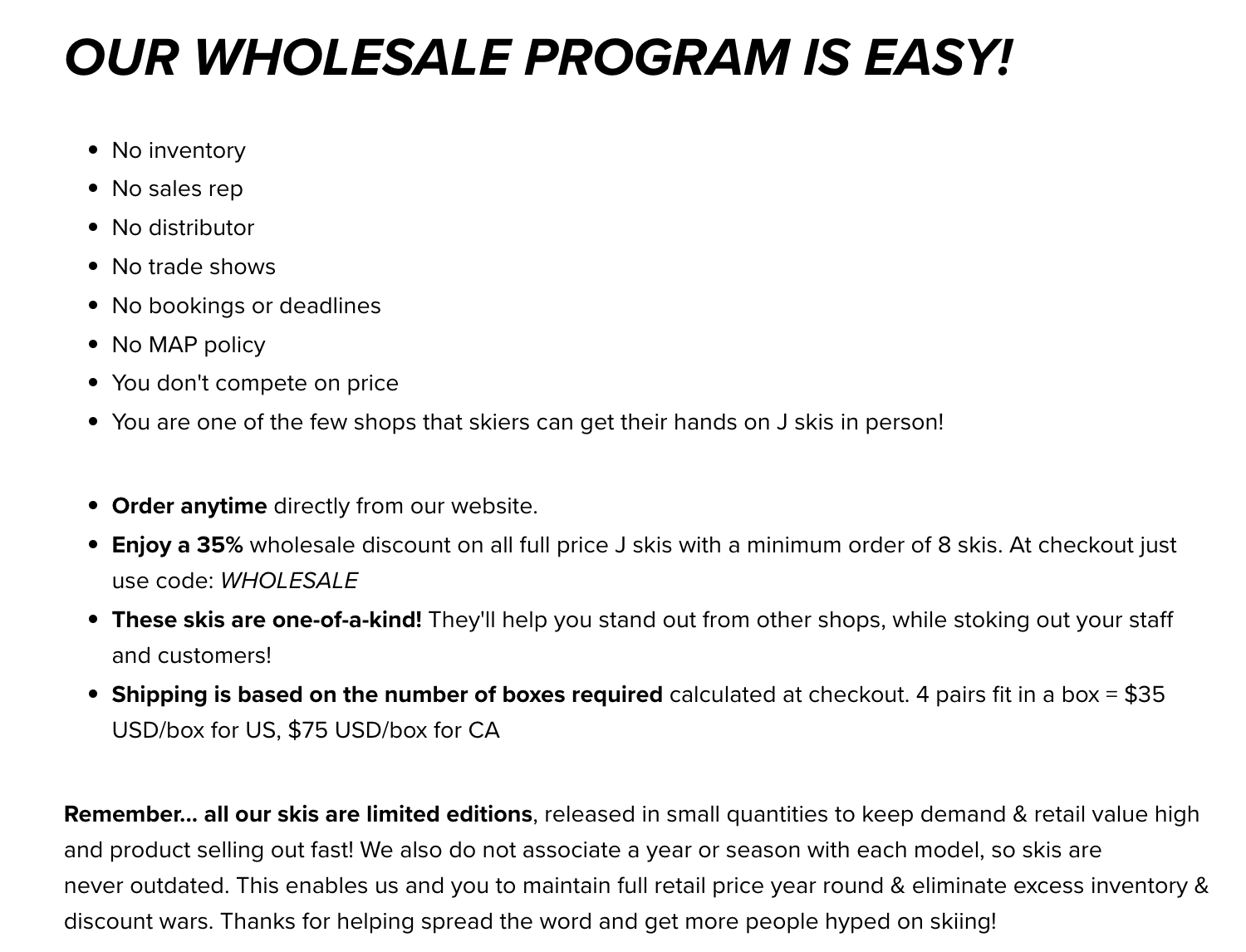

I love the simplicity of their wholesale program.

They give a 35% discount to ANYONE who orders at least 8 pairs of ski’s.

That means REI & the mom & pop ski shop pay the same price for an order.

Gross Profit Estimate

Average Retail Price (including shipping) - $850

Total COGS (Per Pair) - $156.00

Raw Materials - $50.00

Labor & Overhead - $75.00

Packaging / Finishing - $7.50

CA Factory → USA Warehouse - $1.50

DTC Last-Mile Delivery - $22.00

Gross Profit = $694 (81.6%)

Considerations

Short run, small production batches raises their COGS.

Canadian labor, especially for skilled composite/woodwork, is expensive.

Frequent art drops = more time on prepress, proofs, setup, and inventory management.

High fixed costs. Lower variable costs per unit due to ownership, Very high margin once fixed costs are covered.

Differentiation

True craftsmanship is rare to find these days. I have a ton of respect for Jskis.

You can’t fake his passion and craftsmanship. Other brands can’t tell a story as well as he can.

The winning brands over the next decade will have the most compelling brand stories.

———————————————————-

If you're building a physical product brand and want a teardown of JSkis' cost structure — email me at keyan@ironmargin.com and I’ll send you the spreadsheet template I built. Use it to benchmark your own margins.